| Application: | Processing Metal Parts | Table Size: | 800*500mm |

|---|---|---|---|

| Travel: | 600*500*500mm | Distance Between Spindle And Table: | 110-610mm |

| Distance Between Spindle And Column: | 560mm | Spindle Rotation Speed: | 8000/10000/12000/15000rpm |

| Spindle Taper: | BT40 | Spindle Motor: | 7.5kw |

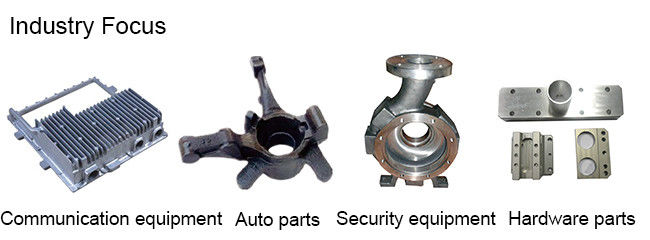

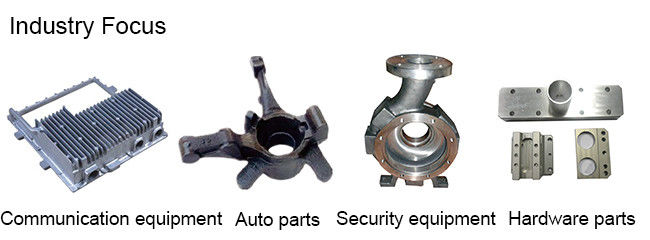

BT40 7.5kw Vertical CNC Machining Center High Efficiency Part Processing Quick detail: 1. High efficiency, high rigidity processing, three axis linear way model 2. L3 series: X/Y/Z Axis are linear slideway, improved running speed and processing efficiency 3. 657L3 and 857L3 model, increase Z axis travel to 700mm and are able to install 4 axis rotary table for complex parts processing 4. 1270L3(BT40 spindle), suitable for large size parts processing, with optional spindle rotation speed(10000/12000rpm) 5. L series: X/Y axis are linear way, Z Axis box way 6. High rigidity machine body to ensure the strong cutting requirements fulfilled under fast operation Product application: 1. It can complete the drilling, milling, boring, reaming, expansion, and other rigid tapping process. 2. So it is suitable for many varieties, medium and small batch production. 3. It can finish the processing of complex, high precision parts. 4. It can be matched the four rotary axis , in order to meet the requirements of special parts. Specification Of Vertical machine center VMC650L

Standard Accessories: Fanuc/MitsubishiController system Full enclosed cover Spindle encoder position system Three axis inner encoder feedback system Auto lubrication system Pneumatic system RS 232 Interface Operation unit Working light Tool and tool box Optional accessories: Siemens controller or other controller system Spindle oil coolant Umbrella type tool magazine Arm type tool magazine Screw type auto conveyor Chain type tool magazine 4 Axis rotary table Ring spray spindle

| Model | Unit | VMC-650L | ||

| Travel | X axis | mm | 600 | |

| Y axis | mm | 500 | ||

| Z axis | mm | 500 | ||

| Distance between spindle and table | mm | 110-610 | ||

| Working table | Table size | mm | 800*500 | |

| Max. Load of table | Kg | 350 | ||

| T slot | Pcs-mm-mm | 3-18-144 | ||

| Positioning accuracy | X/Y/Z axis | mm | 0.008/0.008/0.008 | |

| Repeated positioning accuracy | X/Y/Z axis | mm | 0.005/0.005/0.007 | |

| Spindle | Spindle rotation speed | Rpm | 8000 | |

| Spindle taper | BT40 | |||

| Diameter | mm | Φ130 | ||

| Rivet model | BT40 45° | |||

| Rapid feed | X/Y/Z axis | m/min | 30/30/18 | |

| Cutting feed | X/Y/Z axis | m/min | 10 | |

| Tool magazine | Umbrella type | Size | Tools | 16 |

| Too changing time (T-T) | Sec | 6 | ||

| Max. diameter/ length/weight of tool | mm | 100/200/8 | ||

| Max tool diameter (no tool adjacent) | mm | 180 | ||

| Arm type | Size | Tools | 24 | |

| Tool changing time (T-T) | sec | 3.5s | ||

| Max. diameter/ /length/weight of tool | mm | 80/200/8 | ||

| Max tool diameter (no tool adjacent) | mm | 150 | ||

| Total capacity of electric | KVA | 15 | ||

| Weight of machine | Kg | 5300 | ||

| Dimension | mm | 2750*2380*2600 | ||