| 3 Axis: | Square Way | X Axis Travel: | 1200mm |

|---|---|---|---|

| Y Axis Travel: | 700mm | Z Axis Travel: | 600mm |

| Rapid Feed: | 15/15/12 M/min | Cutting Feed: | 8 M/min |

| Spindle Speed: | 8000rpm | Application: | Making Molds |

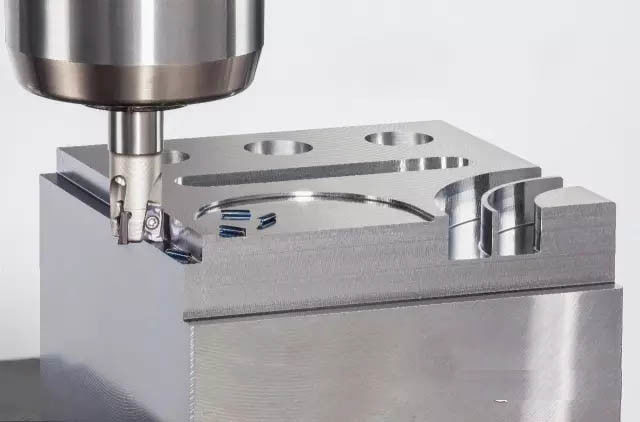

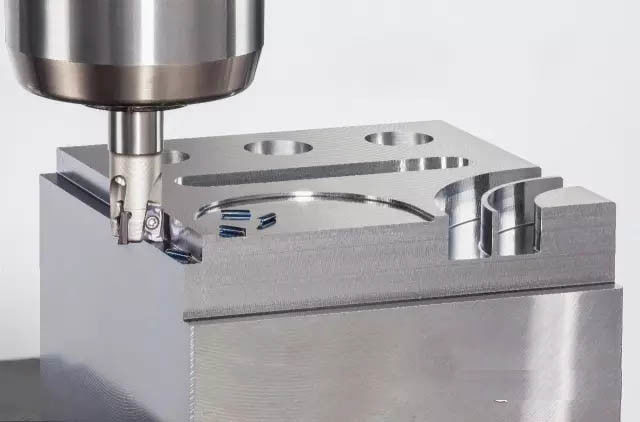

CNC Machine Center VMC1270

1. X,Y,Z Axes slide way are quenched and fixed to mould rail.2. High-rigidity machine body ensure cutting requirements can be met.3. Coupling, spindle bearing, spindle, ball screw, linear slide way, tool magazine, unclamping cylinder and other key parts are imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision.4. Complete product model,from 540 to 1890,suitable for various small to medium mould processing. 5. Modular configuration,can provide customized options to meet different customers processing needs: Spindle water coolant, Gear type spindle-case,12000-15000 rpm/min direct connection spindle.6. This machine center focuses on mould processing,it also suits mechanic parts processing.7. In this serie models above 1580 employ temperature control technique (our patent) to ensure the stability and accuracy for long-hour processing.

1. X,Y,Z Axes slide way are quenched and fixed to mould rail.2. High-rigidity machine body ensure cutting requirements can be met.3. Coupling, spindle bearing, spindle, ball screw, linear slide way, tool magazine, unclamping cylinder and other key parts are imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision.4. Complete product model,from 540 to 1890,suitable for various small to medium mould processing. 5. Modular configuration,can provide customized options to meet different customers processing needs: Spindle water coolant, Gear type spindle-case,12000-15000 rpm/min direct connection spindle.6. This machine center focuses on mould processing,it also suits mechanic parts processing.7. In this serie models above 1580 employ temperature control technique (our patent) to ensure the stability and accuracy for long-hour processing.  1. Taiwan famous brand high speed and high precision spindle. 2. Tool magazine optional 3. High strength resin sand casting. 4. NSK bearing imported from Japan 5. Automatic intermittent lubricate system 6. Fully enclosed cover 7. Fanuc, Simens, Mitsubishi, Syntec CNC control system

1. Taiwan famous brand high speed and high precision spindle. 2. Tool magazine optional 3. High strength resin sand casting. 4. NSK bearing imported from Japan 5. Automatic intermittent lubricate system 6. Fully enclosed cover 7. Fanuc, Simens, Mitsubishi, Syntec CNC control system

Fanuc Controller system8000Rpm spindleFull enclosed coverSpindle encoder position systemThree axis inner encoder feedback systemAuto lubrication systemPneumatic systemRS 232 InterfaceOperation unitRS232 Interface +working lightTool and tool box

Fanuc Controller system8000Rpm spindleFull enclosed coverSpindle encoder position systemThree axis inner encoder feedback systemAuto lubrication systemPneumatic systemRS 232 InterfaceOperation unitRS232 Interface +working lightTool and tool box Siemens controller or other controller systemSpindle oil coolantHeat exchangerUmbrella type tool magazineArm type tool magazineScrew type auto conveyorChain type tool magazine4 Axis rotary tableRing spray spindle

Siemens controller or other controller systemSpindle oil coolantHeat exchangerUmbrella type tool magazineArm type tool magazineScrew type auto conveyorChain type tool magazine4 Axis rotary tableRing spray spindle

1. X,Y,Z Axes slide way are quenched and fixed to mould rail.2. High-rigidity machine body ensure cutting requirements can be met.3. Coupling, spindle bearing, spindle, ball screw, linear slide way, tool magazine, unclamping cylinder and other key parts are imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision.4. Complete product model,from 540 to 1890,suitable for various small to medium mould processing. 5. Modular configuration,can provide customized options to meet different customers processing needs: Spindle water coolant, Gear type spindle-case,12000-15000 rpm/min direct connection spindle.6. This machine center focuses on mould processing,it also suits mechanic parts processing.7. In this serie models above 1580 employ temperature control technique (our patent) to ensure the stability and accuracy for long-hour processing.

1. X,Y,Z Axes slide way are quenched and fixed to mould rail.2. High-rigidity machine body ensure cutting requirements can be met.3. Coupling, spindle bearing, spindle, ball screw, linear slide way, tool magazine, unclamping cylinder and other key parts are imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision.4. Complete product model,from 540 to 1890,suitable for various small to medium mould processing. 5. Modular configuration,can provide customized options to meet different customers processing needs: Spindle water coolant, Gear type spindle-case,12000-15000 rpm/min direct connection spindle.6. This machine center focuses on mould processing,it also suits mechanic parts processing.7. In this serie models above 1580 employ temperature control technique (our patent) to ensure the stability and accuracy for long-hour processing.  1. Taiwan famous brand high speed and high precision spindle. 2. Tool magazine optional 3. High strength resin sand casting. 4. NSK bearing imported from Japan 5. Automatic intermittent lubricate system 6. Fully enclosed cover 7. Fanuc, Simens, Mitsubishi, Syntec CNC control system

1. Taiwan famous brand high speed and high precision spindle. 2. Tool magazine optional 3. High strength resin sand casting. 4. NSK bearing imported from Japan 5. Automatic intermittent lubricate system 6. Fully enclosed cover 7. Fanuc, Simens, Mitsubishi, Syntec CNC control system

| Model | Unit | VMC1270 | ||

| Travel | X axis | mm | 1200 | |

| Y axis | mm | 700 | ||

| Z axis | mm | 600 | ||

| Distance between spindle and table | mm | 150-750 | ||

| Working table | Table size | mm | 1360*700 | |

| Max. Load of table | Kg | 1000 | ||

| T slot | Pcs-mm-mm | 5-18-152.5 | ||

| Positioning accuracy | X/Y/Z axis | mm | 0.01/0.008/0.008 | |

| Repeated positioning accuracy | X/Y/Z axis | mm | 0.008/0.006/0.006 | |

| Spindle | Spindle rotation speed | Rpm | 8000 | |

| Spindle taper | BT50 | |||

| Diameter | mm | Φ155 | ||

| Rivet model | BT40 45° | |||

| Rapid feed | X/Y/Z axis | m/min | 15/15/12 | |

| Cutting feed | X/Y/Z axis | m/min | 8 | |

| Tool magazine | Umbrella type | Size | Tools | 20 |

| Too changing time (T-T) | Sec | 6 | ||

| Max. diameter/ length/weight of tool | mm | 134/250/15 | ||

| Max tool diameter (no tool adjacent) | mm | 185 | ||

| Arm type | Size | Tools | 24 | |

| Tool changing time (T-T) | sec | 3.5s | ||

| Max. diameter/ /length/weight of tool | mm | 110/200/15 | ||

| Max tool diameter (no tool adjacent) | mm | 200 | ||

| Total capacity of electric | KVA | 35 | ||

| Weight of machine | Kg | 9800 | ||

| Dimension | mm | 3560*3300*3100 | ||

Fanuc Controller system8000Rpm spindleFull enclosed coverSpindle encoder position systemThree axis inner encoder feedback systemAuto lubrication systemPneumatic systemRS 232 InterfaceOperation unitRS232 Interface +working lightTool and tool box

Fanuc Controller system8000Rpm spindleFull enclosed coverSpindle encoder position systemThree axis inner encoder feedback systemAuto lubrication systemPneumatic systemRS 232 InterfaceOperation unitRS232 Interface +working lightTool and tool box Siemens controller or other controller systemSpindle oil coolantHeat exchangerUmbrella type tool magazineArm type tool magazineScrew type auto conveyorChain type tool magazine4 Axis rotary tableRing spray spindle

Siemens controller or other controller systemSpindle oil coolantHeat exchangerUmbrella type tool magazineArm type tool magazineScrew type auto conveyorChain type tool magazine4 Axis rotary tableRing spray spindle