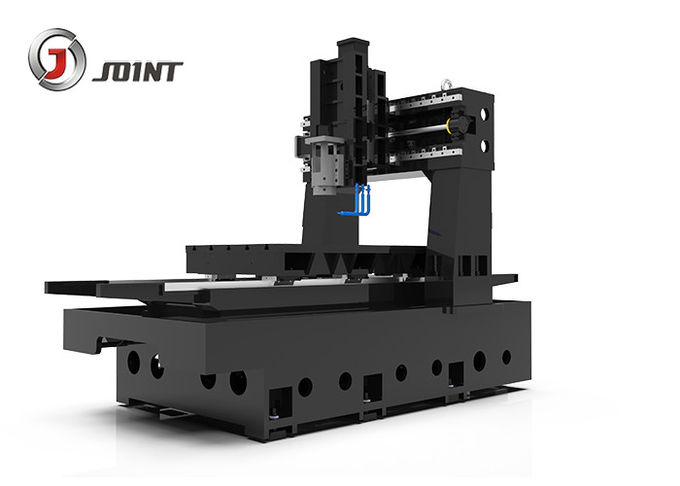

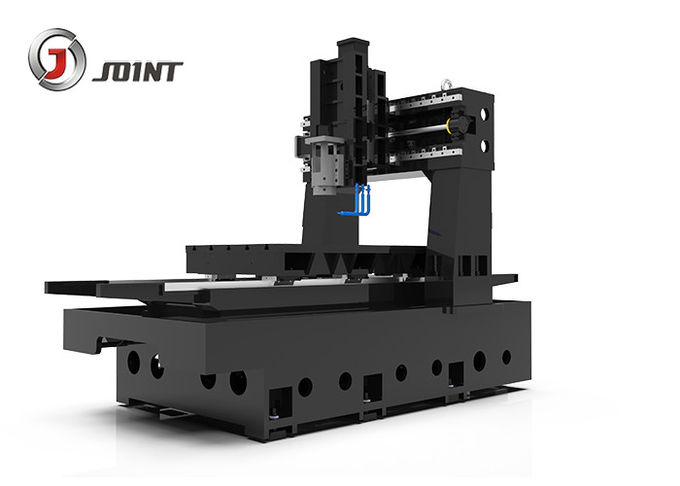

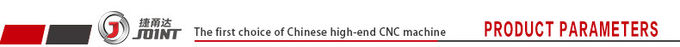

| Name: | Double Column Machine Center | Model: | BTMC-1225 |

|---|---|---|---|

| Table Size: | 900*2500mm | Travel: | 2500*1200*800mm |

| Spindle Rotation Speed: | 8000rpm/ 12000rpm / 15000rpm | Spindle Taper: | BT50/ BT40 |

| Spindle Motor: | 15-18.5kw | Load Weight: | 3000kgs |

| Net Weight: | 15000kgs |

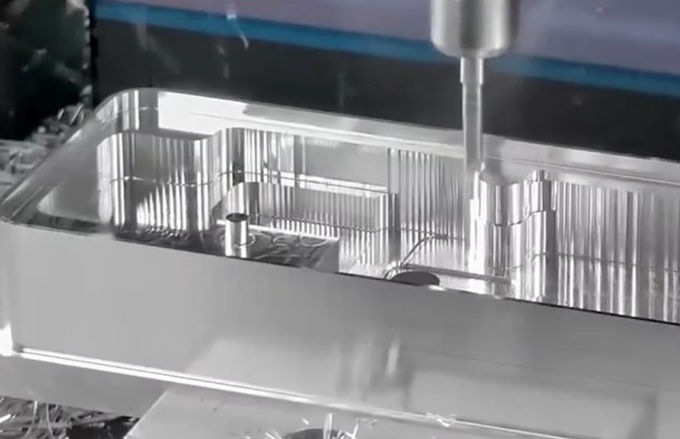

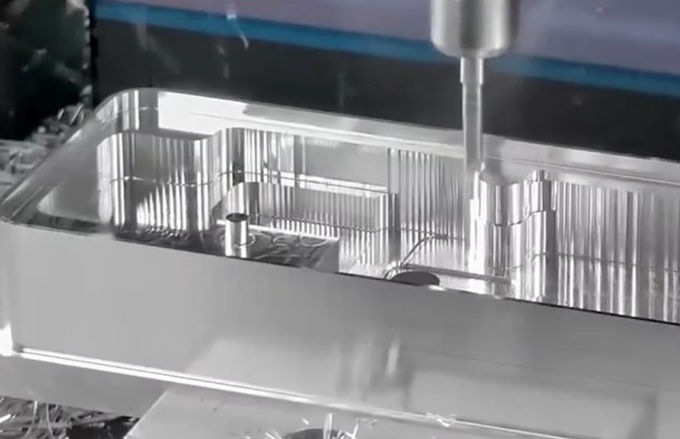

Heavy Duty Double Column CNC Milling Machines , Gantry Type CNC Machine Center BTMC-1225  1. Gantry machine center applies fixed beam type double vertical shafts gantry framework structure with cross layout, stable and reliable machine tool. 2. Grantry machining center is mainly used in large size parts, sheet machining ,disc piece ,housing piece, mold ect. With high accuracy, multi-process, complex shapes. Within one-shot clamping, it can continuouslycomplete milling, drilling, flaring,reaming, boring, tapping, 2D and 3D curve and bevel precision machining. 3. Bed, worktable, vertical shaft, beam, axis ect apply high strength cast iron material. Model is of resin sand technology. Stress is removed by secondary time effect treatment.

1. Gantry machine center applies fixed beam type double vertical shafts gantry framework structure with cross layout, stable and reliable machine tool. 2. Grantry machining center is mainly used in large size parts, sheet machining ,disc piece ,housing piece, mold ect. With high accuracy, multi-process, complex shapes. Within one-shot clamping, it can continuouslycomplete milling, drilling, flaring,reaming, boring, tapping, 2D and 3D curve and bevel precision machining. 3. Bed, worktable, vertical shaft, beam, axis ect apply high strength cast iron material. Model is of resin sand technology. Stress is removed by secondary time effect treatment.

1. FANUC System 2. Heat exchaner in electric control cabinet3. Water tank cooling device 4. Manual pulse generator5. Automatic lubrication device 6. Workong lamp7. Outer protective cover 8. Three-color warning lamp9. Spindle blowing device 10. RS-232 standard output interface11. Handle air gun 12. LCD 13. Water gun 14. Tool and tool box15. Electric control cabinet 16. Operation manual 17. Transformer

1. FANUC System 2. Heat exchaner in electric control cabinet3. Water tank cooling device 4. Manual pulse generator5. Automatic lubrication device 6. Workong lamp7. Outer protective cover 8. Three-color warning lamp9. Spindle blowing device 10. RS-232 standard output interface11. Handle air gun 12. LCD 13. Water gun 14. Tool and tool box15. Electric control cabinet 16. Operation manual 17. Transformer  1. Mitsubishi system 2. ATC (Manipulator) 3. Spindle oil cooling device 4. Water through spindle center device 5. Disk type oil-water separator 6. CNC rotation worktable (the 4th axis) 7. Air conditioner in electric control cabinet 8. fully-enclosed optical scale detecting system 9. Automatic tool length measuting system 10. Manual / Semi*autoatic right-angle head 12. ZF gear box

1. Mitsubishi system 2. ATC (Manipulator) 3. Spindle oil cooling device 4. Water through spindle center device 5. Disk type oil-water separator 6. CNC rotation worktable (the 4th axis) 7. Air conditioner in electric control cabinet 8. fully-enclosed optical scale detecting system 9. Automatic tool length measuting system 10. Manual / Semi*autoatic right-angle head 12. ZF gear box

1. Gantry machine center applies fixed beam type double vertical shafts gantry framework structure with cross layout, stable and reliable machine tool. 2. Grantry machining center is mainly used in large size parts, sheet machining ,disc piece ,housing piece, mold ect. With high accuracy, multi-process, complex shapes. Within one-shot clamping, it can continuouslycomplete milling, drilling, flaring,reaming, boring, tapping, 2D and 3D curve and bevel precision machining. 3. Bed, worktable, vertical shaft, beam, axis ect apply high strength cast iron material. Model is of resin sand technology. Stress is removed by secondary time effect treatment.

1. Gantry machine center applies fixed beam type double vertical shafts gantry framework structure with cross layout, stable and reliable machine tool. 2. Grantry machining center is mainly used in large size parts, sheet machining ,disc piece ,housing piece, mold ect. With high accuracy, multi-process, complex shapes. Within one-shot clamping, it can continuouslycomplete milling, drilling, flaring,reaming, boring, tapping, 2D and 3D curve and bevel precision machining. 3. Bed, worktable, vertical shaft, beam, axis ect apply high strength cast iron material. Model is of resin sand technology. Stress is removed by secondary time effect treatment.

| Model | BTMC-1225 |

| Table size | 900*2500mm |

| X aixs travel | 2500mm |

| Y axis travel | 1200mm |

| Z axis travel | 800mm |

| Gantry width | 1220mm |

| Distance between spindle and table | 120-920mm |

| Spindle rotation speed | 6000rpm (BT40-10000/12000/15000Rpm optional) |

| Spindle taper | BT50 (BT40 Direct connection spindle ) |

| Spindle Motor | 15-18.5kw |

| Work table Tslot | 7-22*125mm |

| X axis rapid feed | 12m/min |

| Y axis rapid feed | 12m/min |

| Z axis rapid feed | 8m/min |

| Cutting feed | 8m/min |

| Positioning accuracy | 0.01mm/m |

| Min.set moving unit | 0.001mm |

| Net weight | 15000kgs |

| Max load of table | 3000kgs |

| Dimension | 8570*3210*3920mm |

1. FANUC System 2. Heat exchaner in electric control cabinet3. Water tank cooling device 4. Manual pulse generator5. Automatic lubrication device 6. Workong lamp7. Outer protective cover 8. Three-color warning lamp9. Spindle blowing device 10. RS-232 standard output interface11. Handle air gun 12. LCD 13. Water gun 14. Tool and tool box15. Electric control cabinet 16. Operation manual 17. Transformer

1. FANUC System 2. Heat exchaner in electric control cabinet3. Water tank cooling device 4. Manual pulse generator5. Automatic lubrication device 6. Workong lamp7. Outer protective cover 8. Three-color warning lamp9. Spindle blowing device 10. RS-232 standard output interface11. Handle air gun 12. LCD 13. Water gun 14. Tool and tool box15. Electric control cabinet 16. Operation manual 17. Transformer  1. Mitsubishi system 2. ATC (Manipulator) 3. Spindle oil cooling device 4. Water through spindle center device 5. Disk type oil-water separator 6. CNC rotation worktable (the 4th axis) 7. Air conditioner in electric control cabinet 8. fully-enclosed optical scale detecting system 9. Automatic tool length measuting system 10. Manual / Semi*autoatic right-angle head 12. ZF gear box

1. Mitsubishi system 2. ATC (Manipulator) 3. Spindle oil cooling device 4. Water through spindle center device 5. Disk type oil-water separator 6. CNC rotation worktable (the 4th axis) 7. Air conditioner in electric control cabinet 8. fully-enclosed optical scale detecting system 9. Automatic tool length measuting system 10. Manual / Semi*autoatic right-angle head 12. ZF gear box