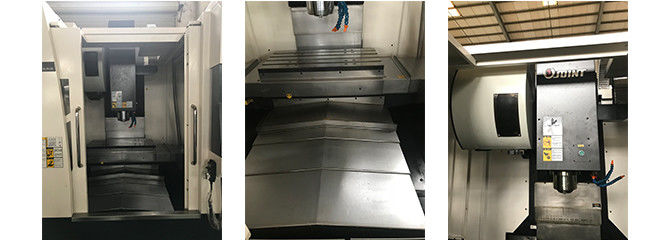

Products Details

| Name: | High Precision Cnc Machine Center H86 | Spindle Connection: | Direct Connection 10000rpm |

| Spindle Taper: | BT40-150 Long Nose Direct Connection Spindle | ATC Type: | 24 Tools Arm Type Tool Magazine |

| Rapid Feed: | 48m/min | Accuracy: | 0.006mm |

| 3 Axis: | Roller Linear Guide Way | Travel: | 800/600/600 |

3 Axis Roller Linear Way H86 Vertical Machine Center BT40 Direct Drive Spindle Quick detail: 1. H86 Vertical machine center adopts Japan’s controller system(Mitsubishi or Fanuc) and its supplementary servo driving and motor, which can realize 3 axis cnc controlled. 2. Material removal rate is 1.5 times of regular cutting machining center, which shorten the parts processing time and period, improve the production efficiency greatly. 3. This machine is widely applied in electronic, machinery, automobile, plane, Aerospace, ship, national defense industry etc. Product features: 1.New designed 3 axis linear guide way, the body structure meets high speed machine center’s “3 high” requirements, which is high static rigidity, high dynamic rigidity and high heat rigidity. 2. Equipped Taiwan famous brand spindle, highest rotation speed is 10000rpm (12000rpm, 15000rpm spindle optional), high precision high strength direct drive coupling, non slip transmission, improves the processing precision. 3. Adopting imported precision bearings and Taiwan quality precision ball screw. 4.3 axis adopts high precision high speed Germany INA heavy load ball screw linear guide way, high rigidity, low noise, low friction, high sensitivity, improves the processing speed and precision. 5.Equipped with high performance Mitsubishi or Fanuc controller system, ensures stable control of the machine, also meet with customer’s requirement on CNC processing function and auxiliary function. 6.X/Y/Z axis adopts Japan’s Mitsubishi or Fanuc motor which is featured for good control, big torque, good following precision, rapid response, good stability. Specification Of Vertical machine center H86 | Model | Unit | H86 |

| Travel | X axis | mm | 800 |

| Y axis | mm | 600 |

| Z axis | mm | 600 |

| Distance between spindle and table | mm | 120-720 |

| Working table | Table size | mm | 900*480 |

| Max. Load of table | Kg | 500 |

| T slot | Pcs-mm-mm | 4-18-100 |

| Positioning accuracy | X/Y/Z axis | mm | 0.006/0.006/0.006 |

| Repeated positioning accuracy | X/Y/Z axis | mm | 0.005/0.005/0.005 |

| Spindle | Spindle rotation speed | Rpm | 8000 |

| Spindle taper | | BT40 |

| Diameter | mm | Φ150 |

| Rivet model | | BT40 45° |

| Rapid feed | X/Y/Z axis | m/min | 48/48/48 |

| Cutting feed | X/Y/Z axis | m/min | 12 |

| Tool magazine | Arm type | Size | Tools | 24 |

| Tool changing time (T-T) | sec | 2.5s |

| Max. diameter/ /length/weight of tool | mm | 80/200/8 |

| Max tool diameter (no tool adjacent) | mm | 150 |

| Total capacity of electric | KVA | 15 |

| Weight of machine | Kg | 5500 |

| Dimension | mm | 2300*3145*2800 |

Standard Accessories: Fanuc/MitsubishiController system 10000rpm direct drive spindle 24 tools arm type tool magazine Heat exchanger Spindle oil coolant Full enclosed cover Spindle encoder position system Three axis inner encoder feedback system Auto lubrication system Pneumatic system RS 232 Interface Operation unit Working light Tool and tool box Optional accessories: Siemens controller or other controller system Screw type auto conveyor Chain type tool magazine 4 Axis rotary table Ring spray spindle

High Accuracy Surface Grinder,

Metal surface grinders,

Portable grinding machine,

m lathe,

CNC manufacturing,

m spindle quill travel,

axis gantry milling machine,

High precision lathe with three grades gear speed design,

m Lathe,

High speed machining center,