| Name: | Gantry Type Double Column Machine Center | Model Name: | BTMC-1525 |

|---|---|---|---|

| Table: | 2000*1200mm | X/Y/Z Axis Travel: | 2000/1650/800mm |

| Width Of Gantry: | 2000mm | Spindle Taper: | BT50 |

| Rotation Speed: | 6000rpm | Spindle Motor: | 22kw |

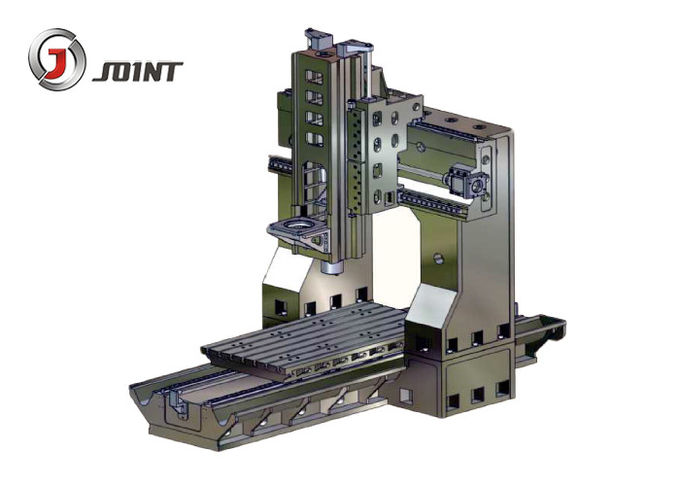

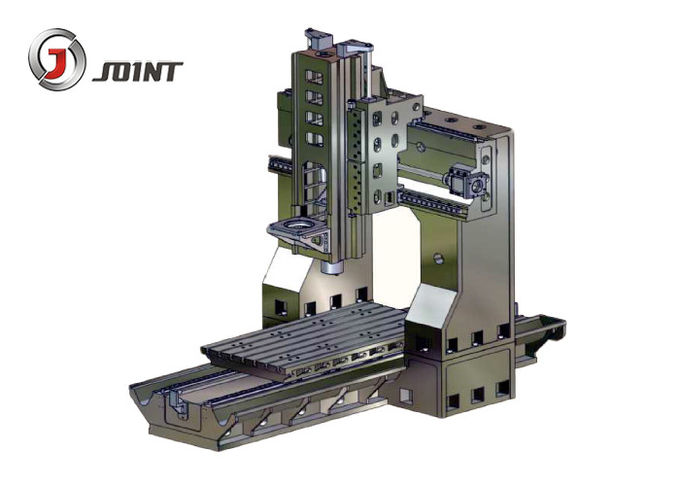

Big sizegantry typeCNC machine centerBTMC-1525  Large castings, such as worktable, bed, pillar, cross beam and slide pillow, are made of high-grade resin sand. The inner cavity of the castings is honeycomb- like composite arrangement structure. The design is advanced. All the castings are aged and tempered twice. The residual internal stress is eliminated to stabilize the material, ensure the stability of workpiece processing accuracy and machine tool life. The worktable is fixed and the machine table occupies a small area.

Large castings, such as worktable, bed, pillar, cross beam and slide pillow, are made of high-grade resin sand. The inner cavity of the castings is honeycomb- like composite arrangement structure. The design is advanced. All the castings are aged and tempered twice. The residual internal stress is eliminated to stabilize the material, ensure the stability of workpiece processing accuracy and machine tool life. The worktable is fixed and the machine table occupies a small area.  1. This type of machine adopts advanced technology, typical of good performance, reliable structure, easy operation, convenient maintenance, is widely used in mechanical processing department for medium and heavy black non-ferrous metal plane, inclined plane and the groove surface milling, etc.. 2. It can use all kinds of standard cutter, and has large cutting torque and cutting depth. 3. The machine bed, table, bar are manufactured with high-quality cast iron, and have twoquenching to eliminate the stress and deformation.

1. This type of machine adopts advanced technology, typical of good performance, reliable structure, easy operation, convenient maintenance, is widely used in mechanical processing department for medium and heavy black non-ferrous metal plane, inclined plane and the groove surface milling, etc.. 2. It can use all kinds of standard cutter, and has large cutting torque and cutting depth. 3. The machine bed, table, bar are manufactured with high-quality cast iron, and have twoquenching to eliminate the stress and deformation.

Precision machinery manufacturer since 1995. Your reliant expert on moulding and machining equipemnt!

Precision machinery manufacturer since 1995. Your reliant expert on moulding and machining equipemnt!

Large castings, such as worktable, bed, pillar, cross beam and slide pillow, are made of high-grade resin sand. The inner cavity of the castings is honeycomb- like composite arrangement structure. The design is advanced. All the castings are aged and tempered twice. The residual internal stress is eliminated to stabilize the material, ensure the stability of workpiece processing accuracy and machine tool life. The worktable is fixed and the machine table occupies a small area.

Large castings, such as worktable, bed, pillar, cross beam and slide pillow, are made of high-grade resin sand. The inner cavity of the castings is honeycomb- like composite arrangement structure. The design is advanced. All the castings are aged and tempered twice. The residual internal stress is eliminated to stabilize the material, ensure the stability of workpiece processing accuracy and machine tool life. The worktable is fixed and the machine table occupies a small area.  1. This type of machine adopts advanced technology, typical of good performance, reliable structure, easy operation, convenient maintenance, is widely used in mechanical processing department for medium and heavy black non-ferrous metal plane, inclined plane and the groove surface milling, etc.. 2. It can use all kinds of standard cutter, and has large cutting torque and cutting depth. 3. The machine bed, table, bar are manufactured with high-quality cast iron, and have twoquenching to eliminate the stress and deformation.

1. This type of machine adopts advanced technology, typical of good performance, reliable structure, easy operation, convenient maintenance, is widely used in mechanical processing department for medium and heavy black non-ferrous metal plane, inclined plane and the groove surface milling, etc.. 2. It can use all kinds of standard cutter, and has large cutting torque and cutting depth. 3. The machine bed, table, bar are manufactured with high-quality cast iron, and have twoquenching to eliminate the stress and deformation.

| Model | BTMC-1525 |

| Table size | 1200*2000mm |

| X/Y/Z travel | 2000*1650*800mm |

| Distance between tool head and table | 115-915mm |

| Work table Y slot (NO.-size*pitch) | 7-22*170mm |

| Width of gantry | 1650mm |

| Spindle rotation speed | 6000 rpm/min |

| Spindle Taper | BT50 |

| Spindle Motor | 22KW |

| X/Y/Z axis ball screw size | 6310/5010/5010 |

| X/Y axis guide way | 45/55 |

| X/Y/Z axis Rapid feed | 8/10/12 m/min |

| Positioning accuracy | 0.01mm |

| X/Y/Z axis Cutting feed | 8 m/min |

| Dimension | 7200*3700*4300mm |

| Net weight | 24000kg |

| Max load of table | 3000kg |

| 1) Fanuc-OI MF(5) Control System with motor and drive | 9) Automatic lubrication system |

| 2) 6000RPM/22KW/BT50 Taiwan brand belt type spindle | 10) Heat exchange |

| 3) X/Y axis are roller linear way, Z axis is box way | 11) Warning light |

| 4) 1200*2000mm worktable area | 12) Tool and tool box |

| 5) Screw type chip conveyor | 13) Working light |

| 6) Pneumatic system | 14) RS232 Interface |

| 7) Work piece coolant system | 15) Operation manual |

| 8) Spindle oil chiller |

Precision machinery manufacturer since 1995. Your reliant expert on moulding and machining equipemnt!

Precision machinery manufacturer since 1995. Your reliant expert on moulding and machining equipemnt!