Products Details

| Name: | Vertical Machining Center | Table Size: | 700*420mm |

| X/Y/Z Axis Travel: | 600*400*420mm | Distance Between Spindle And Table: | 170-590mm |

| Spindle Taper: | BT40-120 | T-Slot: | 3-18-125 |

| ATC Type: | 24 Tool Arm Type Tool Magazine | Application: | Processing Parts |

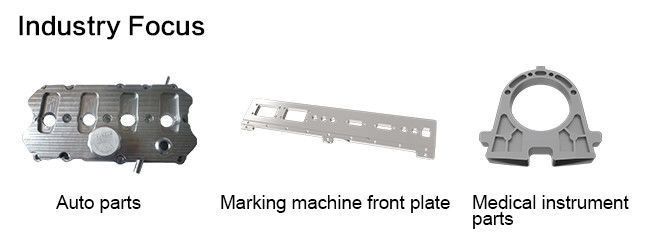

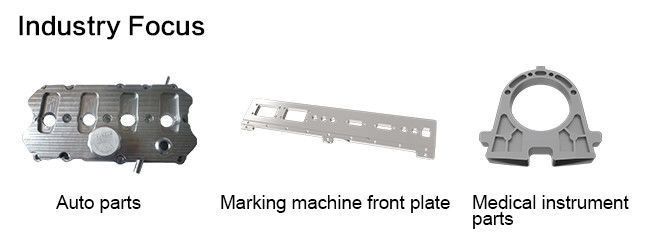

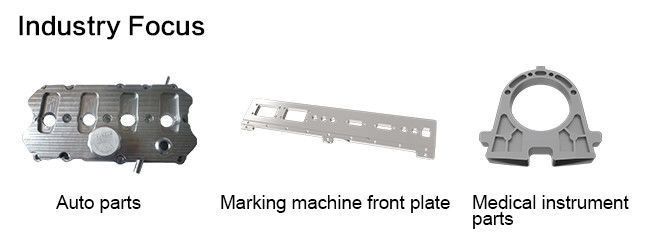

BT40 7.5KW Vertical Machining Center Processing Parts V65 with 24 tools ATC Product features: 1. The feed axis machining center for X, Y, Z coordinate control, spindle servo motor powered, magazine capacity of 24 tools. 2. V65 Can achieve a variety of disc-type, plate type, shell, cam, mold and other complex parts in a single setup, completethe drilling, milling and processing a variety of processes, boring, expanding, reaming, tapping, etc. 3. V65 is Suitable for varieties ofsmall batch production of complex, high-precision machining of parts to better show its superiority. Product advantage: 1. Finite Element Analysis The structural parts are analyzed and designed by the advanced Finite Element Analysis.It provides a detailed analysis for structural stress / strain conditions, and ensures excellentmachine rigidity and lifetime stability.2. Pretensioned ballscrews on X, Y, Z axes ensure accuracy and eliminate positioning error. 3. The endface of spindle stock, screw support faces and block contact faces are fully handscraped to increase machining accuracy and feeding smoothness.4. The machine structure is constructed from high quality Meehanite cast iron and stressreleased to ensure great rigidity and precision..5.Over sized column and bed, assuring extra high rigidity of machine frame. Specification Of Vertical machine center V65 | Model | Unit | V65 |

| Travel | X axis | mm | 600 |

| Y axis | mm | 400 |

| Z axis | mm | 420 |

| Distance between spindle and table | mm | 170-590 |

| Working table | Table size | mm | 700*420 |

| Max. Load of table | Kg | 300 |

| T slot | Pcs-mm-mm | 3-18-125 |

| Positioning accuracy | X/Y/Z axis | mm | 0.006/0.006/0.006 |

| Repeated positioning accuracy | X/Y/Z axis | mm | 0.005/0.005/0.005 |

| Spindle | Spindle rotation speed | Rpm | 10000 |

| Spindle taper | | BT40 |

| Diameter | mm | Φ140 |

| Rivet model | | BT40 45° |

| Rapid feed | X/Y/Z axis | m/min | 48/48/48 |

| Cutting feed | X/Y/Z axis | m/min | 15 |

| Tool magazine | Arm type | Size | Tools | 24 |

| Tool changing time (T-T) | sec | 2.5s |

| Max. diameter/ /length/weight of tool | mm | 80/250/8 |

| Max tool diameter (no tool adjacent) | mm | 150 |

| Total capacity of electric | KVA | 15 |

| Weight of machine | Kg | 3500 |

| Dimension | mm | 2350*2100*2600 |

Standard Accessories Fanuc Controller system 10000Rpm spindle 24tools arm type tool magazine Spindle oil cooler Heat exchanger Full enclosed cover Spindle encoder position system Three axis inner encoder feedback system Auto lubrication system Pneumatic system RS 232 Interface Operation unit RS232 Interface working light Tool and tool box

Wholesale Edm Spark Erosion,

BTMC- milling machines,

Vertical milling machine with intelligent control,

Grinding equipment suppliers.,

x x mm dimension,

High-speed CNC machine,

BT machine spindle,

Best Vmc850 Quotes,

rpm double column machining center,

Industrial grade erosion machine,