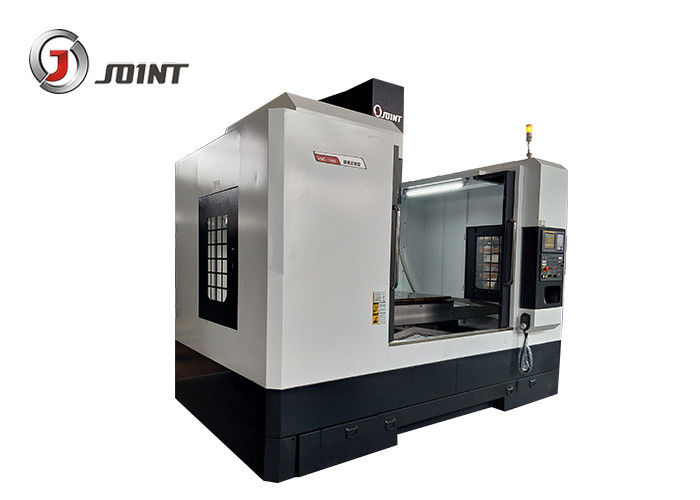

Shenzhen Joint Technology Co., Ltd. is a leading manufacturer, supplier, and factory of high-speed machining centers designed for mold making applications. Our machining centers feature cutting-edge technology, including high-performance spindles, precision ball screws, and advanced control systems, delivering unparalleled speed, accuracy, and efficiency.

With a range of machine sizes and configurations available, our high-speed machining centers are ideal for all types of mold making applications, from complex automotive and aerospace molds to simple injection molds. They offer fast and precise cutting, high accuracy, and excellent surface finish, delivering exceptional results.

Our machining centers are built to the highest quality standards, ensuring maximum reliability and durability, even under heavy usage. We also offer customizable options to suit our customers' specific needs, making our machines the perfect choice for any mold making operation.

Choose Shenzhen Joint Technology Co., Ltd. for superior quality, exceptional performance and reliable customer service. Contact us today for more information.